Analyses

Porosity/Inclusion Analysis and analysis according to P 201/VW 50097

The Porosity/Inclusion Analysis allows material defects such as blowholes or bubbles in castings to be detected and analyzed. The entire volume data is analyzed in 3D, pores or inclusions are detected irrespective of their absolute grey value and, in a further step, they are subjected to a plausibility check. Pores or inclusions are color-coded in all 2D and 3D views of the data set. Detailed information about each individual defect such as its volume, projected size and position are provided in a table.

The analysis also allows the users to analyze the parts according to the standards defined by the VDG (German Association of Foundry Specialists) or Volkswagen AG. This special tool has been officially approved by VW. With the help of the new feature, fast non-destructive CT-based defect analysis will replace traditional, destructive and time-consuming defect analysis procedures based on the micrograph imaging.

Coordinate measurement

Coordinate Measurement Module has been designed to fit ruled geometries such as planes or cylinders to the respective structures of a scanned object in order to perform measurements between these objects. All results from coordinate measuring can be documented both graphically and statistically in a user-defined measurement report. Ruled geometries and measurements can be presented not only in 3D views but can also be visualized in 2D views as in conventional engineering drawings.

The Coordinate Measurement Module also provides an algorithm allowing the object surface to be determined on the basis of local gray value thresholds. Thus it is able to also deal reliably with scans of multi-material assemblies. In addition, it allows objects to be positioned in a user-defined coordinate system or to be aligned to a CAD model or another CT scan.

Wall Thickness Analysis

The Wall Thickness Analysis allows to examine objects areas in which the wall thickness is within a user-defined interval between a minimum and maximum permissible wall thickness. The resulting components are color-coded in the 2D and 3D views of the data set.

Nominal/Actual Comparison

Nominal/Actual Comparison Module is a unique tool for a direct comparison of volume data with a CAD model or a second volume data set. The data set to be examined is color-coded according to its deviation from the specification. A report containing statistical data as well as 2D and 3D images of the critical areas is generated.

Fiber Composite Material Analysis

With the Fiber Composite Material Analysis Module it is possible to inspect fiber materials non-destructively and at the same time obtain all sorts of highly reliable information on the internal structure of your part. In detail, the following parameters can be calculated: local and global fiber orientation, local and global fiber concentration, deviation from predefined reference orientation, local fiber orientation in a plane projection and many other statistical parameters such as fiber distribution. The analysis results can be displayed and reported in various ways: display the local fiber orientation in 2D or 3D, color-coded, as vectors or tensors, view histograms of the orientation distribution, analyze the fiber concentration in a color coded plot, access line plots of individual components of the orientation tensor.

Foam Structure Analysis

The Foam Structure Analysis module of VGSTUDIO MAX allows the segmentation of CT data intotopologically disconnected components which can be visualized and statistically analyzed. The structural analysis of foams represents a significant example of application of this kind of analysis. As acommon feature, all foams exhibit a cellular structure realized by a solid or liquid medium whichembeds gas-filled cavities. These cavities typically occupy a large volume fraction of the foamand may either be completely surrounded by material or - as in the case of open-cell foams - belinked to adjacent cells. Another type of cellular structure which may also be targeted by thefoam structure analysis consists of typically densely packed objects of a solid material whichare immersed in a background medium like air. Real-world examples of these structures are fillmaterials, loose sediments, or drill samples.

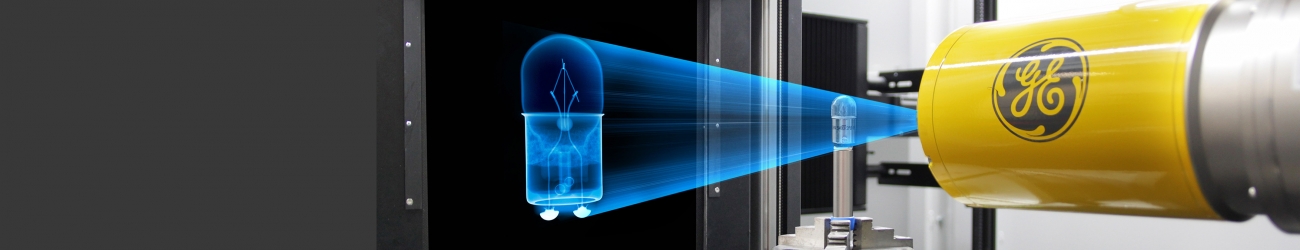

Analysis of the soldered joints

This analysis is performed on Microme|x microfocus X-ray inspection system. The innovative and unique features together with an extremely high positioning accuracy make the system an effective and reliable solution for a wide spectrum of 2D and 3D tasks: inspection of soldered joints, R&D, failure analysis, process and quality control...

Mold correction

With the help of computed tomography it is possible to save costs of mold correction. Using the software tools, the scanned part is compared with the nominal CAD model of the part and the manufacturing deviations of the shape are detected. Manually selected surfaces with intolerable deviations are subsequently used to design a new modified mold. Although this is not an entirely automatic process, this approach is currently a big trend in the industry. Our laboratory is now testing a software tool designed specifically for this application.

Battery inspection

Non-destructive 3D inspection, multiscale imaging, defect identification, tracking electrode degradation.