Equipment

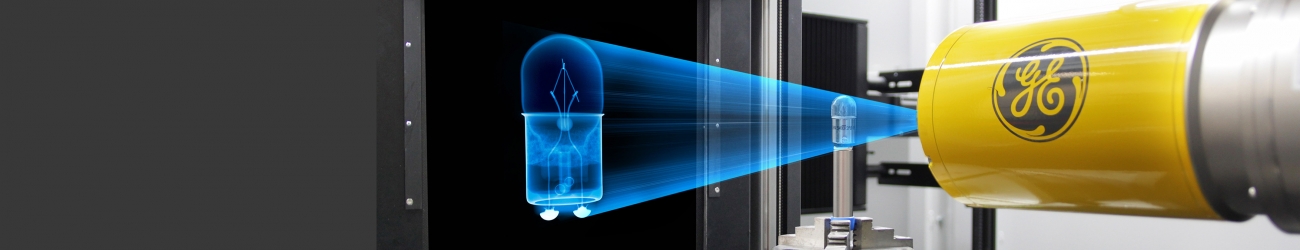

Waygate Technologies phoenix v|tome|x L450

Specifications

- Precise granite-based 7 axes manipulation system for heavy sample handling

- Cabinet crane

- Air-conditioned cabinet, Anti-vibration system

- Scatter correction, Helical scanning, 2D inspection package

- Detector: flat panel dynamic 41|200: 2000 x 2000 px, pixel size 200 μm

- 450 kV / 450 W MESO-Focus X-ray tube

- 450 kV / 1500 W minifocus X-ray tube

Limits

- Maximum scanning volume: Ø800 x 1250 mm

- Maximum sample height: 2 m

- Maximum sample weight: 200 kg

- Minimal focal spot: 63 µm

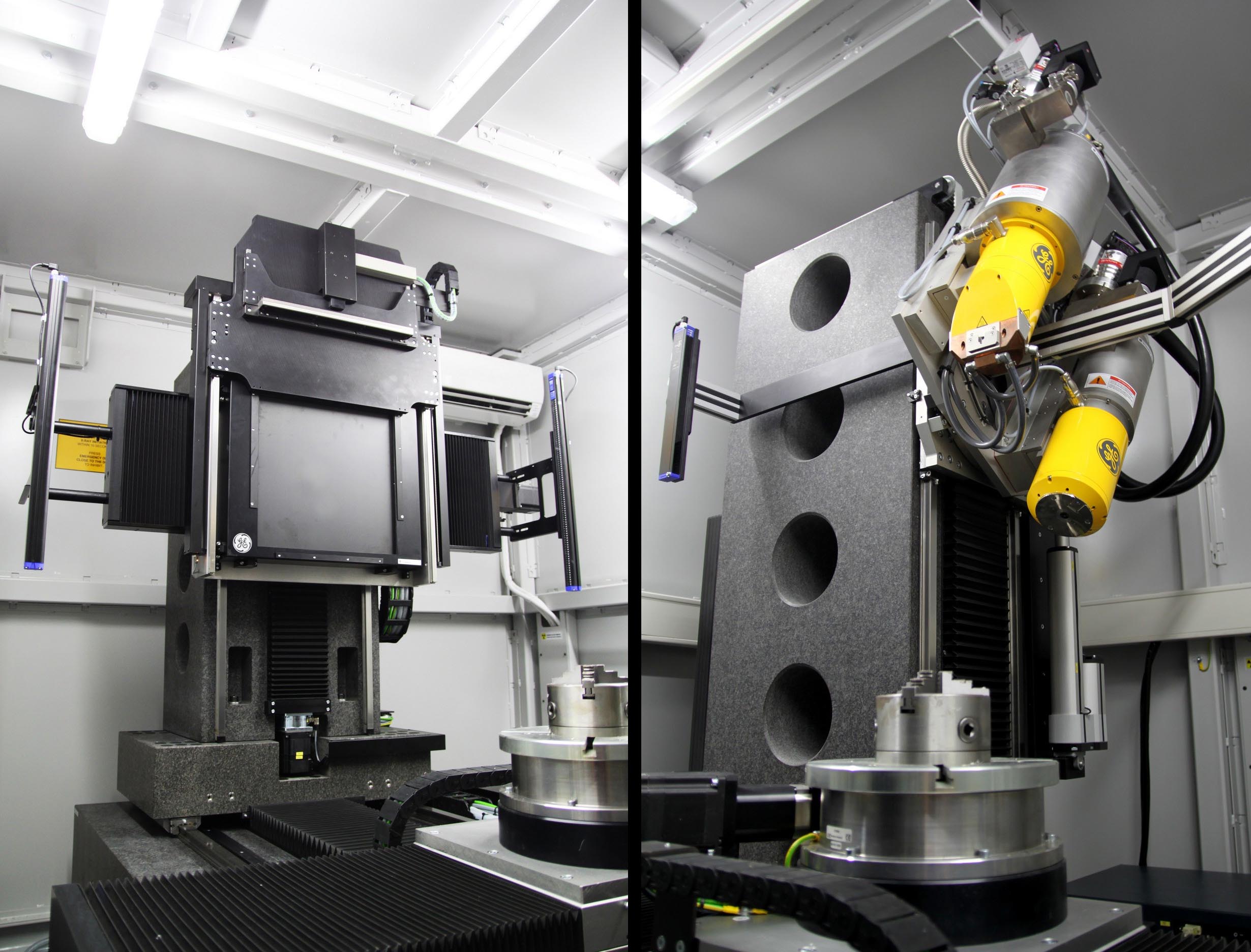

GE phoenix v|tome|x L240

Specifications

- granite-based 7-axis manipulator for long-term stability and highest precision

- detector: flat panel dynamic 41|100: 4000 x 4000 px, pixel size 100 μm

- air-conditioned cabinet

- cluster of 4 GPUs – faster CT data reconstruction

- 240 kV / 320 W microfocus tube

- 180 kV / 15 W nanofocus tube

Limits

- samples up to 500 x 800 mm and 50 kg

- min. voxel size 2 µm for 240 kV tube, 1 µm for 180 kV tube

Virtual tour through laboratory

GE phoenix v|tome|x M300

Specifications

- granite-based 5-axis manipulator

- Temperature stabilized digital GE DXR detector array

- cluster of 4 GPUs – faster CT data reconstruction

- 300 kV / 500 W microfocus tube

Limits

- samples up to 360 x 600 mm and 50 kg

- min. voxel size 1 µm

Intended upgrade to metrology edition with a measurement accuracy of 4+L/100 µm referring to VDI 2630 guideline

RIGAKU nano3DX

Specifications:

- Sample stage: automatic 5-axis stage

- Stage rotation axis accuracy: <0.5 μm

- Detector: X-ray CCD camera

- Dynamic range: 16 bit

- Number of pixels: 3300 × 2500

- Linear pixel size: 0.27 µm, 0.54 µm, 1.08 µm, 2.16 µm

- Field of view: 0.7 × 0.9 mm, 1.4 × 1.8 mm, 2.8 × 3.6 mm, 5.6 × 7.2 mm

- Rotatory target: Cr, Cu and Mo

- Tube voltage: 20 to 50 kV

- Tube current: up to 30 mA

Data analyses:

- Quantitative analytic software of 3D images nano3DCalc

- Quantitative measurement (volume, surface area, orientation and centre of gravity location)

- Imaging software of 3D images INTAGE Realia Professional

Virtual tour through laboratory

Thermo Fisher Scientific Heliscan

Specifications:

- X-ray source: 20–160 kV, power 8 W

- flat panel detector 3072 × 3072 pixels, dynamic range 16bit

- highly precise stage for helical path

- voxel resolution up to 0.8 µm

- limits: sample diameter 0.5–240 mm, maximum load 3 kg, no stitching needed for samples up to 100 mm in height

Helical scanning trajectory enables to produce a continuous geometrically accurate 3D image of tall samples, without stitching. The patented iterative reconstruction technology provides a critical image resolution and a high signal-to-noise acquisition.

Virtual tour through laboratory

Microme|x microfocus X-ray inspection system

Specifications:

- 180 kV / 20 W high-power microfocus tube with up to 0,5 µm detail detectability

- Combined 2D / 3D CT operation

- Brilliant live images by high dynamic temperature-stabilized GE DXR digital detector with 30 fps (frames per second)

- Precise manipulation

- Optional offset|scan capability to scan bigger parts or the same size parts with higher resolution

- Advanced planarCT option for slice or multislice package evaluation without overaying structures

The phoenix microme|x is a high-resolution 180 kV microfocus X-ray inspection system for real time inspection of solder joints and electronic components. Innovative and unique features and an extreme high positioning accuracy make the system the effective and reliable solution for a wide spectrum of 2D and 3D inspection tasks: R&D, failure analysis, process and quality control.