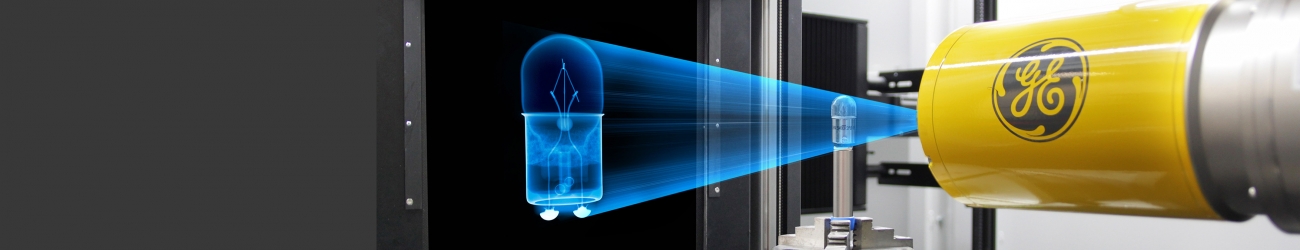

State of the art software solution that predicts and prevents system events in advance. CEITEC researchers are testing it with world leaders in the NDT-Field

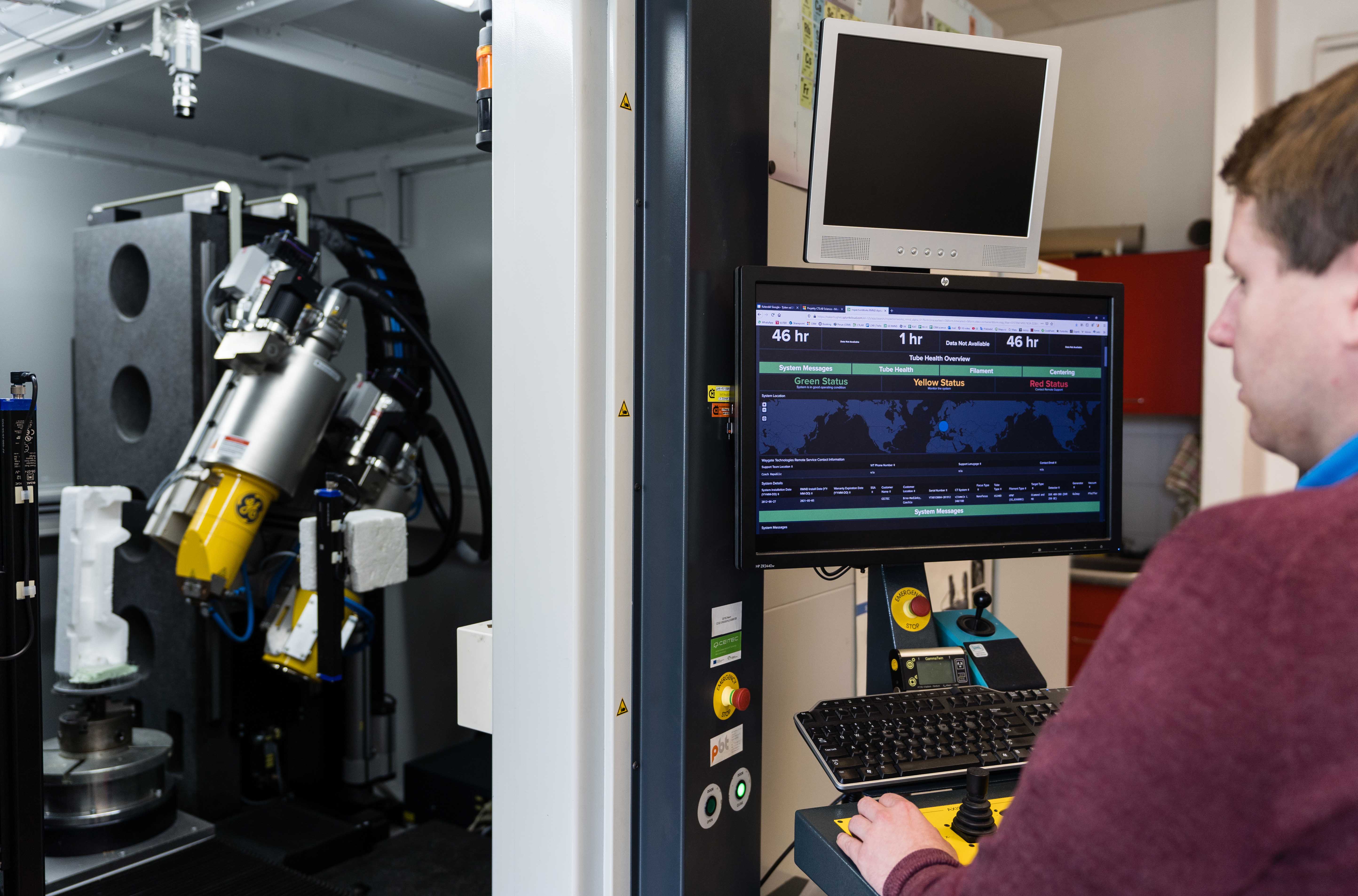

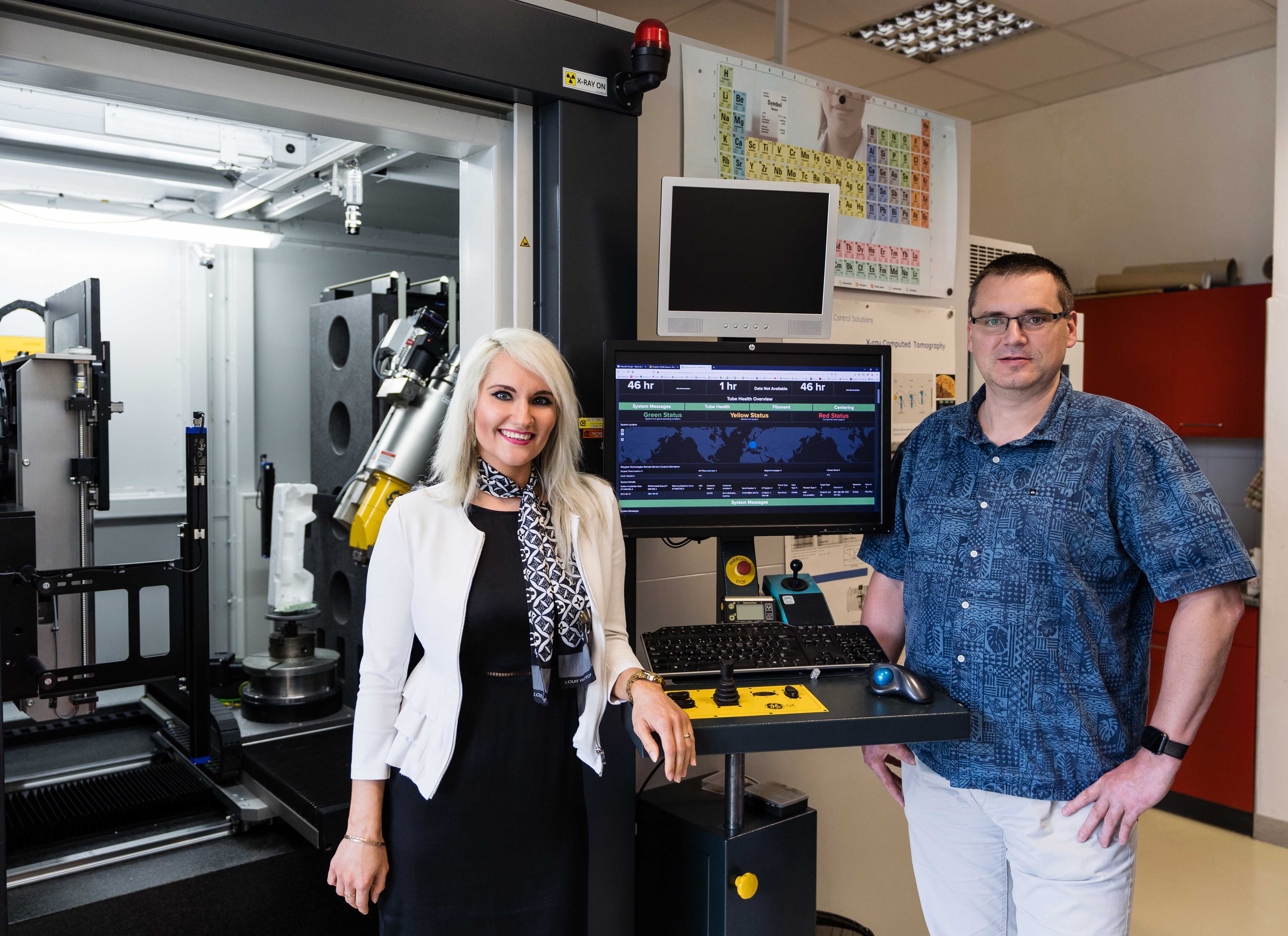

Ensure safe and reliable operation of the system with minimal downtime? Know the problem before it occurs? Researchers from the Laboratory of Computed Tomography at CEITEC BUT are the first in Europe to install the remote diagnostic software solution created by Waygate Technologies. The software solution monitors the life functions of the system and wear of components. The researchers are part of the Alpha Program and are shaping the development of this software solution specially designed for better sustainability of Computed tomographic devices.

Since 2012, researchers from CEITEC BUT have been cooperating with Waygate Technologies, the global market leader for industrial computed tomography, according to 2020 best practices award from Frost & Sullivan. Thanks to this partnership, the researchers have been involved in the development and testing of new functions of computed tomography systems for almost ten years. The success of the current collaboration is evidenced by the fact that they are now among the first to have the software solution known as InspectionWorks Remote Monitoring and Diagnostics (IW RMND).

This current cooperation brings great benefits to both parties. Experts from Waygate Technologies enrich their statistics on the use of the software solution in practice, and Brno scientists can closely monitor how the devices behave, predict events and optimise system and user performance. As a result, they enhance their measurement modes to extend component lifespan and to maximize the use of X-ray tube consumables. This ultimately secures the performance availability and in parallel saves maintenance costs, spare parts on the device which in the end also reduces the carbon footprint of the system.

"The software solution we are currently involved in developing and testing is the first step towards the so-called predictive service. Based on objective wear criteria, each CT machine will report when some of its parts or components are nearing the end of their lifespan and need replacement or maintenance.” Explains Jozef Kaiser, head of the research group Advanced Instrumentation and Methods for Materials Characterization, whose members test software at CEITEC.

“With the IW RMND solution we aim to predict and prevent system events from happening, increasing as such the reliability of our systems and giving back full transparency and security to our customers. IW RMND is also inline with our aim to reduce the carbon footprint as through IW RMND certain Onsite visits are made redundant and also the predictive maintenance will reduce spares consumption - We are truly excited to bring this to Market as a full software solution in 2022” Angelique Mesch and Florian Toelle, Product Managers creating and shaping this Software Solution.

“With the IW RMND solution we aim to predict and prevent system events from happening, increasing as such the reliability of our systems and giving back full transparency and security to our customers. IW RMND is also inline with our aim to reduce the carbon footprint as through IW RMND certain Onsite visits are made redundant and also the predictive maintenance will reduce spares consumption - We are truly excited to bring this to Market as a full software solution in 2022” Angelique Mesch and Florian Toelle, Product Managers creating and shaping this Software Solution.

The main goal of remote diagnostic access is therefore mainly to predict and optimize the operability of the system using machine learning, sophisticated algorithms, and finally, the creation of a digital twin. The software is in line with current industry trends as well as with Industry 4.0 related initiatives, which covers digitization and related production automation. Researchers at CEITEC BUT have been developing this direction in recent years within other research groups. Soon, for example, they will have a new research and innovation centre available within the RICAIP project, connecting artificial intelligence with industrial robotics using equipment worth CZK 450 million.

Original Press Release by CEITEC here.