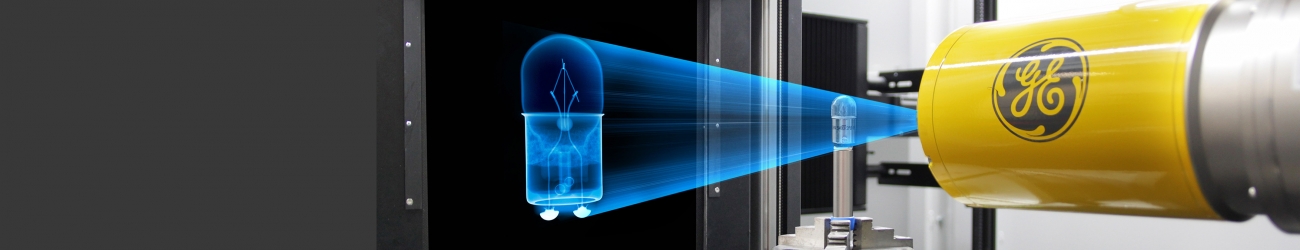

Industrial X-ray Computed Tomography: A Modern Tool for Safety and Quality in Industry

What is Industrial X-ray Computed Tomography?

Industrial X-ray computed tomography (CT) is an advanced non-destructive testing method that uses X-ray radiation to create detailed 3D models of the internal structures of objects. Unlike traditional X-ray imaging, which provides only a two-dimensional view, CT scanning allows for the visualization and analysis of individual layers and structures within an object with incredible precision.

What are the Benefits in Industry?

1. Safety and Quality: CT scanning can detect even the smallest defects, cracks, or inconsistencies within materials and products without the need to cut or destroy the object. This is crucial for ensuring the safety and quality of products, particularly in sensitive industries such as aerospace, automotive, and healthcare.

2. Cost and Time Efficiency: The ability to conduct detailed analyses and inspections without destroying objects reduces the costs associated with scrap and rework. The speed and efficiency of CT scanning also shorten the time required to identify issues, accelerating the development and production process.

3. Improvement of Manufacturing Processes: Data obtained from CT scans can be used to optimize manufacturing processes. Manufacturers can gain a better understanding of how their products function on a microstructural level, allowing for improvements that enhance overall quality and performance.

4. Development and Testing of Prototypes: Industrial tomography is invaluable in the development and testing of prototypes. It enables engineers to quickly identify and address problems in the early stages of development, leading to better designs and faster time-to-market.

5. Archiving and Documentation: CT scanning allows for the creation of digital archives of products and their components. This is particularly useful for retrospective analysis, ensuring compliance with standards, or in legal disputes.

Conclusion

Industrial X-ray computed tomography represents a revolutionary technology that ensures high quality, safety, and efficiency in modern industry. Its application offers a wide range of benefits, from improving manufacturing processes to conducting detailed analyses and optimizing products. With this advanced tool, companies can better understand their products, leading to higher customer satisfaction and improved business outcomes.