Industries

Industrial X-ray Computed Tomography: A Modern Tool for Safety and Quality in…

14.08.2024

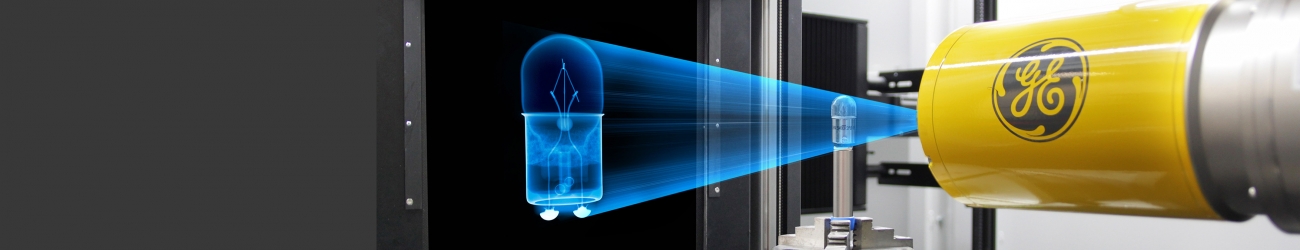

What is Industrial X-ray Computed Tomography?Industrial X-ray computed tomography (CT) is an advanced non-destructive testing method that uses X-ray radiation to create detailed 3D models of the…

Read more »

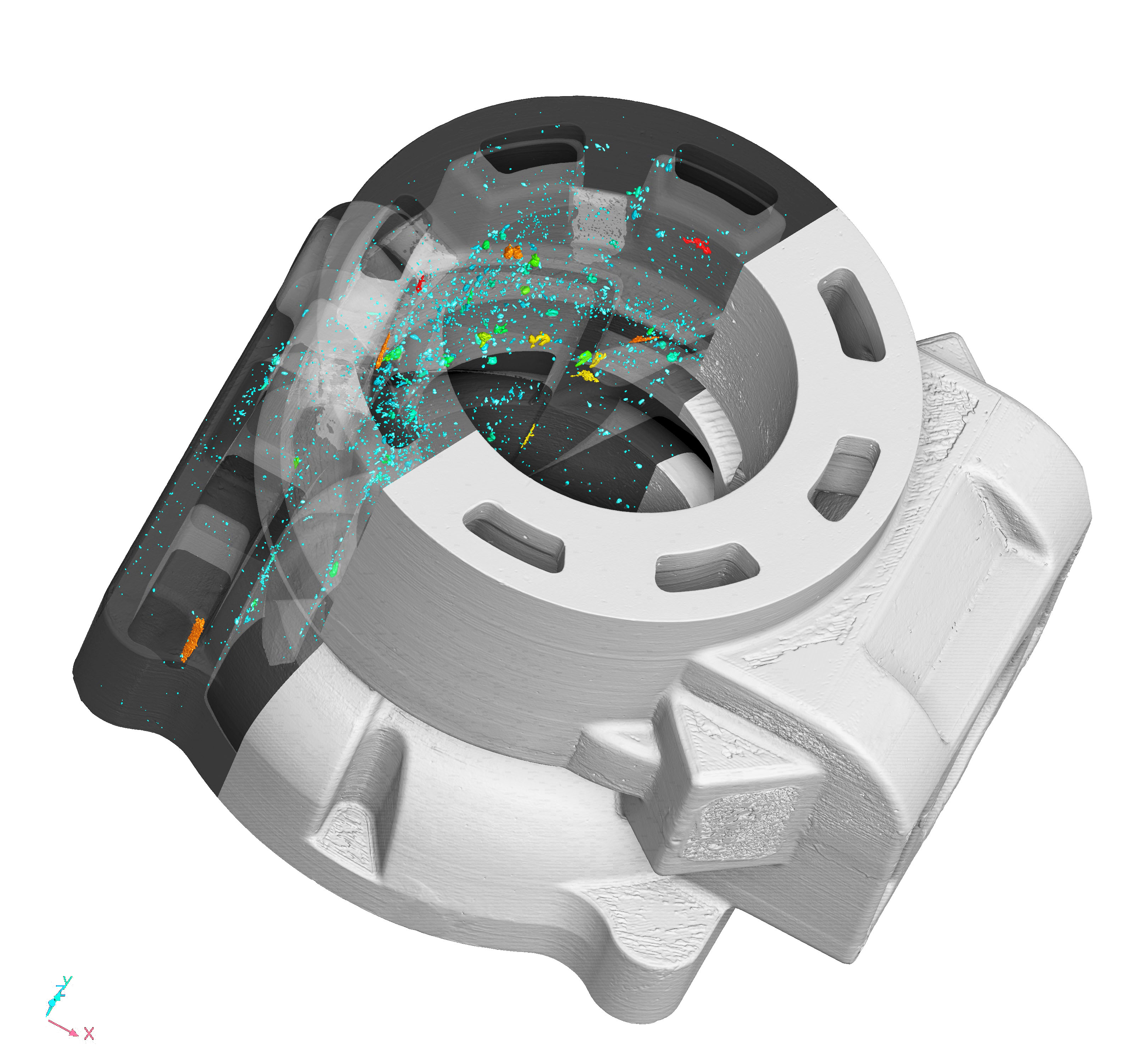

Automotive Industry

In the automotive industry, CT technology is used to scan a wide range of products, including engine components, transmission systems, and fuel injectors. It is also applied to inspect electrical assemblies, such as sensors and circuit boards, as well as structural parts like aluminum castings, composite materials, and welded joints. This allows for detailed examination of internal geometries, detection of porosity, cracks, and other defects, ensuring the highest standards of quality and performance.

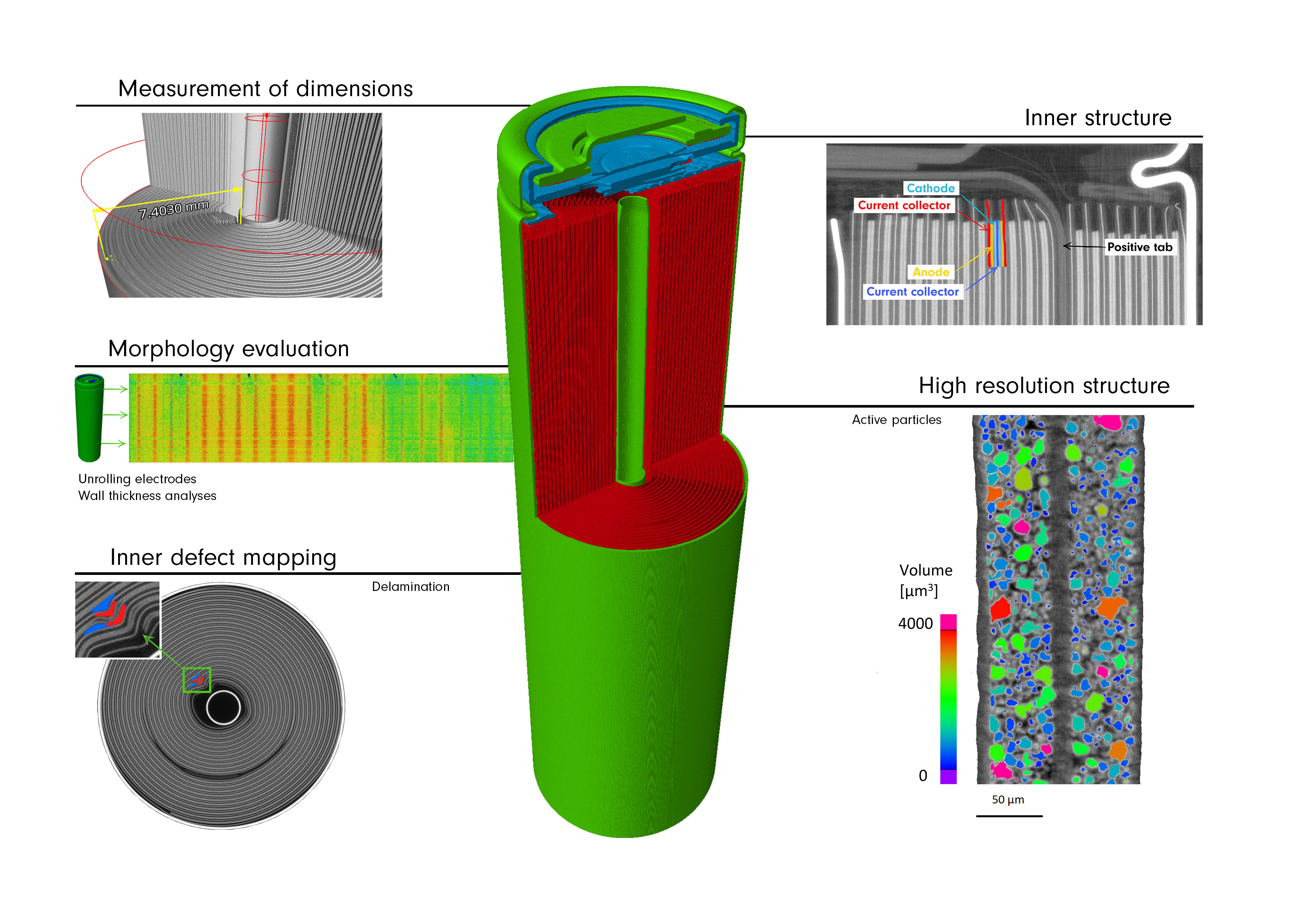

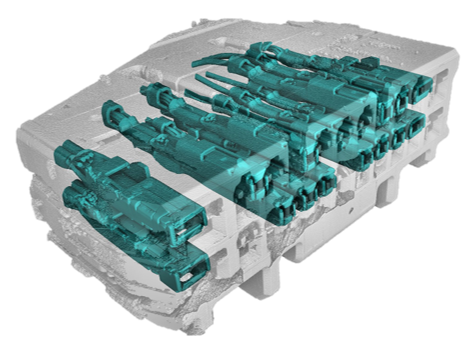

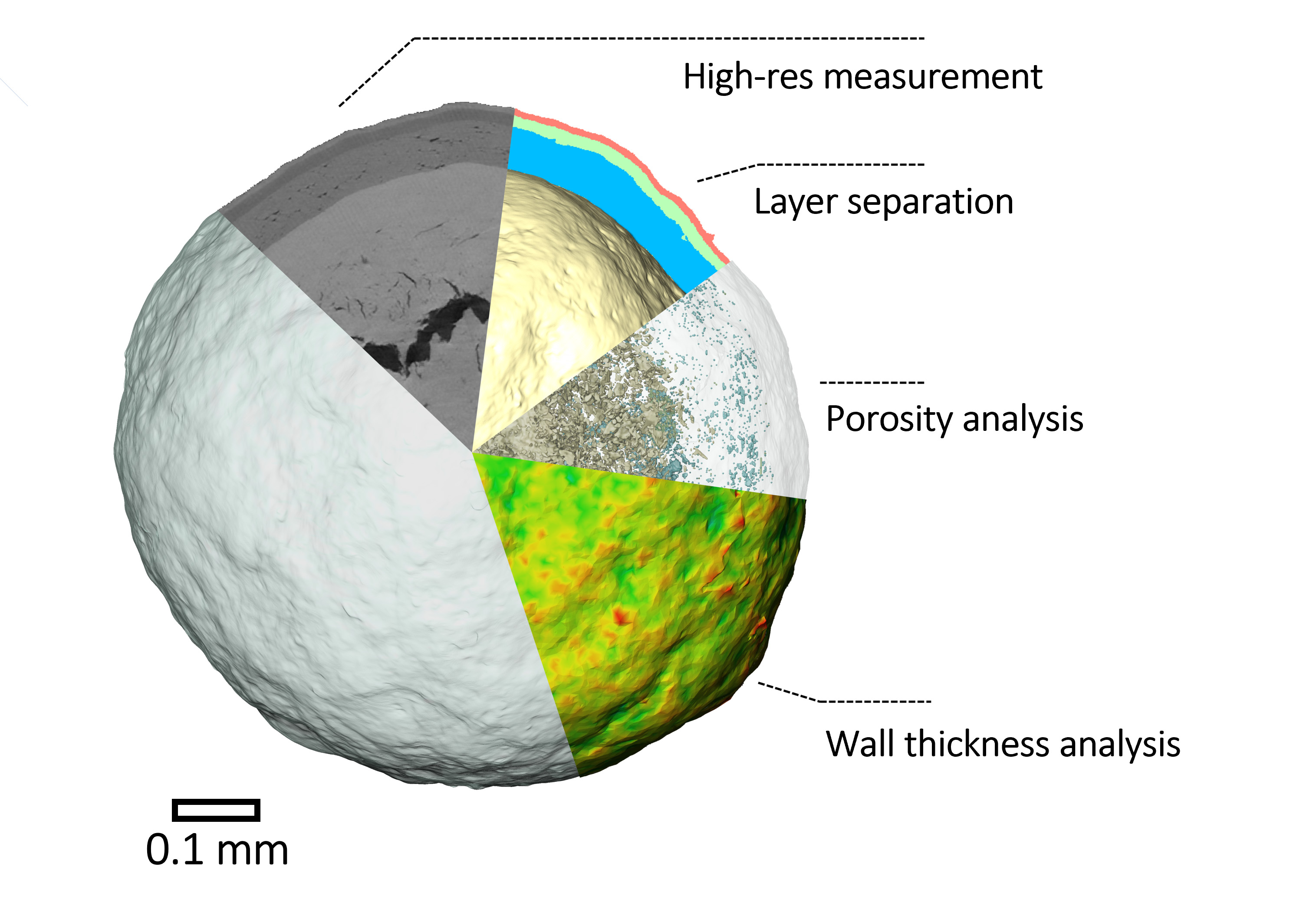

Battery Industry

The most challenging aspects of battery development include ensuring material consistency, detecting internal defects, and optimizing the performance and safety of complex cell structures. CT technology can be a game-changer in this field by providing high-resolution, non-destructive imaging, which allows for precise internal inspection and detailed analysis. This advanced diagnostic capability helps identify and address issues early in the development process, ensuring higher quality and reliability in the final product.

Electronics

Computed tomography (CT) is a powerful tool in electronics for non-destructive 3D visualization and analysis of various components and assemblies. It enables the detection of disconnected contacts, inspection of soldering joints, and examination of the inner geometry of capacitors with high precision. CT scans provide detailed images of processors and other intricate parts, allowing for thorough quality control and failure analysis. The technology is also used to assess porosity in solder, measure the area of penetration in dielectrics, and inspect other critical features such as wire bonds, vias, and microelectromechanical systems (MEMS). CT can reveal manufacturing defects, material inconsistencies, and structural weaknesses that are otherwise invisible. This detailed information aids in optimizing manufacturing processes, ensuring reliability, enhancing performance, and extending the lifespan of electronic products.

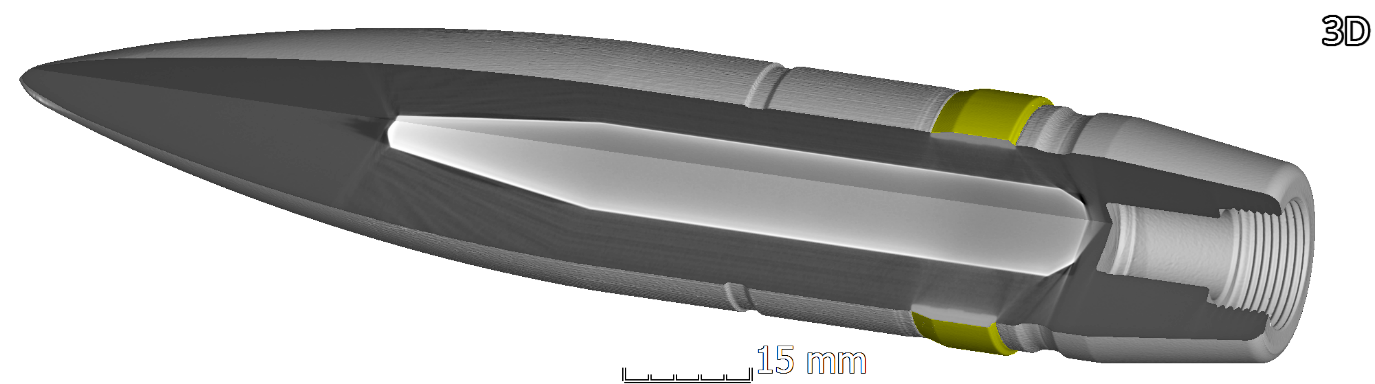

Defense Industry

In the defense industry, CT scanning is often used to inspect and test advanced materials and components used in aircraft and spacecraft, such as composite parts, titanium alloys, and ceramic composites, to ensure their integrity and reliability. The high-resolution images provided by CT scanning allow defense manufacturers to detect internal defects, such as cracks or porosity, which can be critical to the structural integrity of these complex components. In particular, CT scanning is used to inspect the internal structure of stealth aircraft components, such as radar-absorbent materials and coatings, to ensure they meet stringent requirements for electromagnetic compatibility and stealth capabilities.

Aircraft Industry

In the aircraft industry, computed tomography (CT) scanning is commonly used to inspect complex components such as engine parts, landing gear, and hydraulic systems, particularly in the production and maintenance of commercial and military aircraft. The high-resolution imaging capabilities of CT scanners enable technicians to non-destructively inspect these components for internal damage or defects, which is crucial for ensuring the safety and reliability of aircraft operations. Additionally, CT scanning is used to verify the quality and integrity of additive manufacturing (3D printing) parts, such as aircraft components like brackets, fasteners, and other small parts, which require precise inspection to meet stringent aerospace standards.

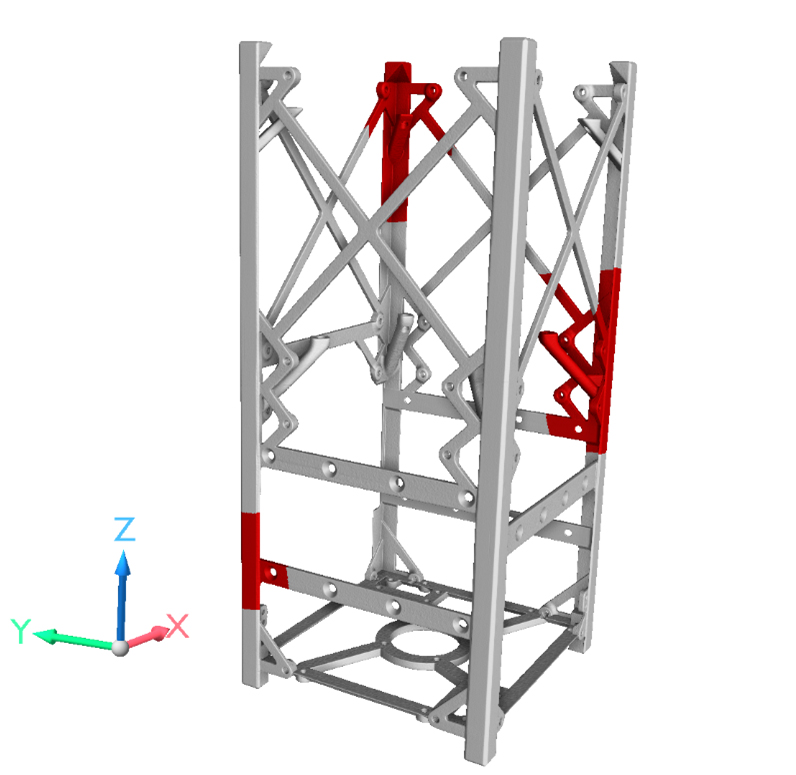

Space Industry

In the space industry, CT scanning is widely used to non-destructively inspect and analyze complex components such as turbine blades, engine vanes, and satellite components, allowing for the detection of internal defects and wear patterns that could compromise performance or safety. The high-resolution imaging capabilities of CT scans enable space engineers to visualize the internal structure of these components, helping to identify issues such as cracks, corrosion, and porosity that may not be visible to the naked eye. By using CT scanning, space manufacturers can reduce the need for destructive testing, minimize downtime for maintenance and repair, and ensure that critical components meet rigorous quality and safety standards.

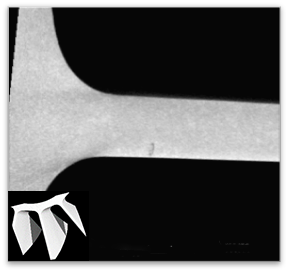

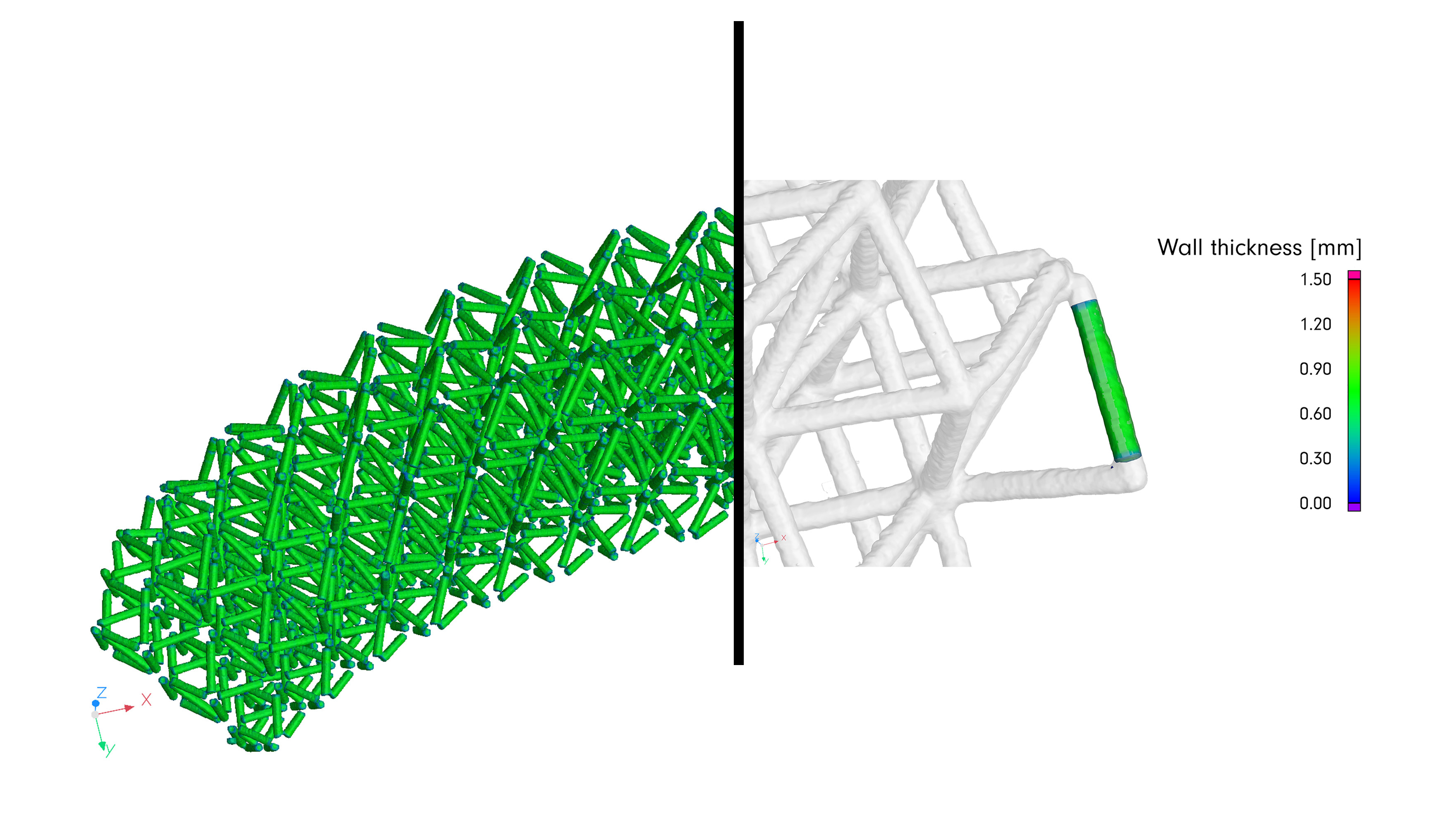

Additive Manufacturing

Additive manufacturing allows for the creation of complex geometries and internal structures that are difficult or impossible to inspect using traditional methods, making CT scanning a crucial tool for quality control and validation. CT scanning provides a non-destructive way to inspect the internal structure and features of additively manufactured parts, revealing defects and potential issues that may not be visible to the naked eye. The unique ability of CT scanning to non-invasively visualize the internal details of additively manufactured parts has enabled the creation of products that were previously impossible to inspect, such as lattice structures and hollow tubes with complex internal geometries.

Pharmacy

Computed tomography (CT) is increasingly used in pharmacy for non-invasive 3D visualization of pharmaceutical formulations and processes. It allows detailed examination of drug delivery systems, such as the internal structure of tablets and capsules, ensuring quality control and consistency. CT scans of developing formulations can monitor the distribution and behavior of active ingredients over time. Furthermore, CT provides valuable 3D information on the microstructure of materials used in drug production, aiding in the design and optimization of new pharmaceutical products and delivery mechanisms. CT is also instrumental in testing packaging, allowing for the inspection of seals, the detection of defects, and the verification of protective functions, ensuring the integrity and safety of pharmaceutical products throughout their shelf life.

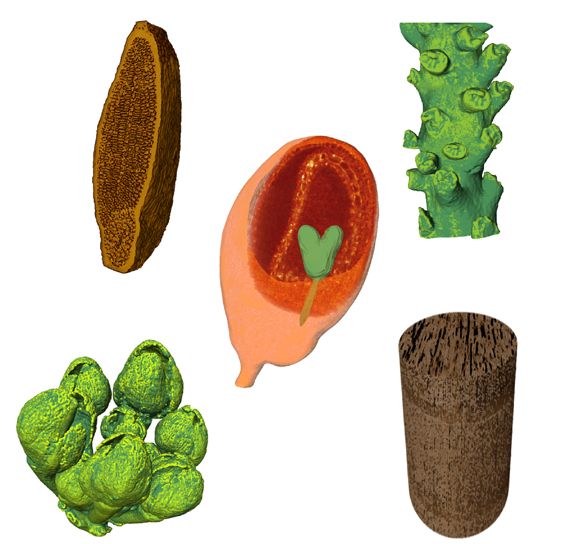

Agriculture

Computed tomography (CT) has become a valuable tool in botany for non-destructive 3D visualization of plant structures. It enables detailed imaging of root systems, providing insights into their growth patterns and interactions with the soil. CT scans of growing plants and seeds allow researchers to monitor developmental processes in real-time, capturing dynamic changes in morphology. Additionally, CT can be used to obtain precise 3D information about specific plant parts, such as stems, leaves, and internal tissues, facilitating advanced studies in plant physiology and pathology.

Reverse Engineering

Computed Tomography (CT) technology is a handy tool in industrial reverse engineering because it allows engineers to non-invasively scan and reconstruct the internal structure of complex components, revealing detailed information about their internal geometry, material composition, and defects. By using CT scans, engineers can accurately reverse-engineer parts and products, even those with intricate or hard-to-reach internal features, without damaging or disassembling them. The high-resolution data generated by CT scans enable engineers to analyze and improve the design of existing products, optimize manufacturing processes, and develop new products with improved performance, durability, and reliability.