Research

Biology

Computed tomography (CT) is a crucial tool in biology, offering non-invasive 3D visualization and analysis of biological structures. It allows for the detailed examination of bones and soft tissues, enabling the creation of accurate 3D models that are essential for studying anatomical features and developmental processes. CT scans can track the course of ossification in different developmental stages, providing insights into bone growth and formation. This technology is also instrumental in the development of bone substitutes and the evaluation of implants, ensuring they meet biological compatibility and functional requirements.

In addition to bone analysis, CT is used to characterize soft tissues, such as muscles, organs, and blood vessels, allowing for a comprehensive understanding of their structure and function. CT can also investigate foreign inclusions in animal bodies, such as microplastics, providing valuable data on environmental impacts on health. By offering a detailed view of internal biological structures, CT advances research in areas like developmental biology, regenerative medicine, and environmental biology, contributing to improved health outcomes and a deeper understanding of life processes.

3D models and analyses

The micro CT data allows to create aprecise 3D model of the individual organs or complex structures. Utilization of professional software enables various analyses including measurements of lengths, volumes, wall thicknesses and comparison of shapes. All of these analyses together with the histological methods give a complex description of samples. Our activities are focused on the implementation of special industrial tools on biological tasks, and on introducing new procedures of data interpretation such as 3D printing (Tesařová et al., Journal of Instrumentation 2016) and interactive 3D PDF (Tesařová et al., Scientific reports 2019).

Lower jaw of chameleon embryo, the wall thickness analysis was applied to analyse the thickness of the developing teeth. (Kavková et. al., Scientific reports 2020).

Lower jaw of chameleon embryo, the wall thickness analysis was applied to analyse the thickness of the developing teeth. (Kavková et. al., Scientific reports 2020).

Staining protocols

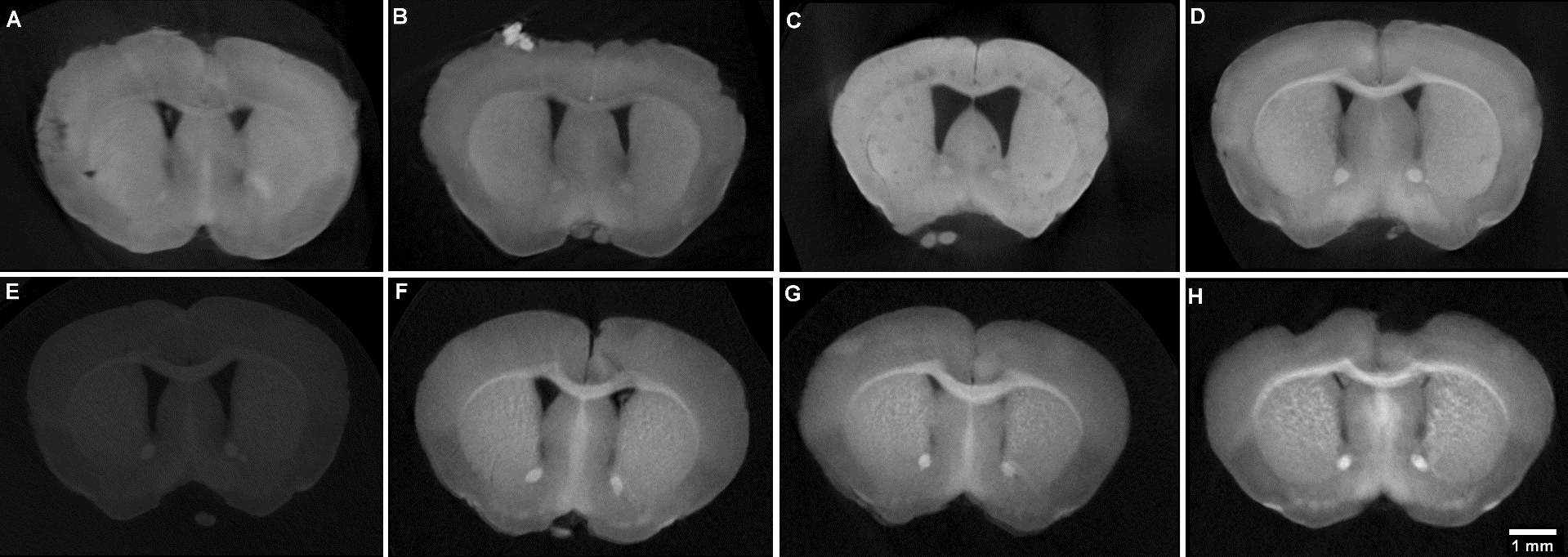

A micro CT scan of a sample in its native state reveals information only about the hard tissues like teeth and bones due to their X-ray absorption properties. For soft tissues the contrast enhanced micro CT imaging has to be involved. Staining solutions with high proton number elements like iodine and phosphotungstic acid areusedin contrasting solutions (Zikmund et. al., Journal of Instrumentation 2018) but the staining procedure has to be optimised for each organ or tissue interest. We mostly deal with exploring new protocols focused mainly on visualization of cartilage (Kaucka et al., Elife 2018), liver, brain and heart.

Comparison of the coronal sections of stained mouse brain following different staining protocols using solutions of iodine and phosphotungstic acid (Zikmund et. al., Journal of Instrumentation 2018).

Comparison of the coronal sections of stained mouse brain following different staining protocols using solutions of iodine and phosphotungstic acid (Zikmund et. al., Journal of Instrumentation 2018).

Tissue engineering

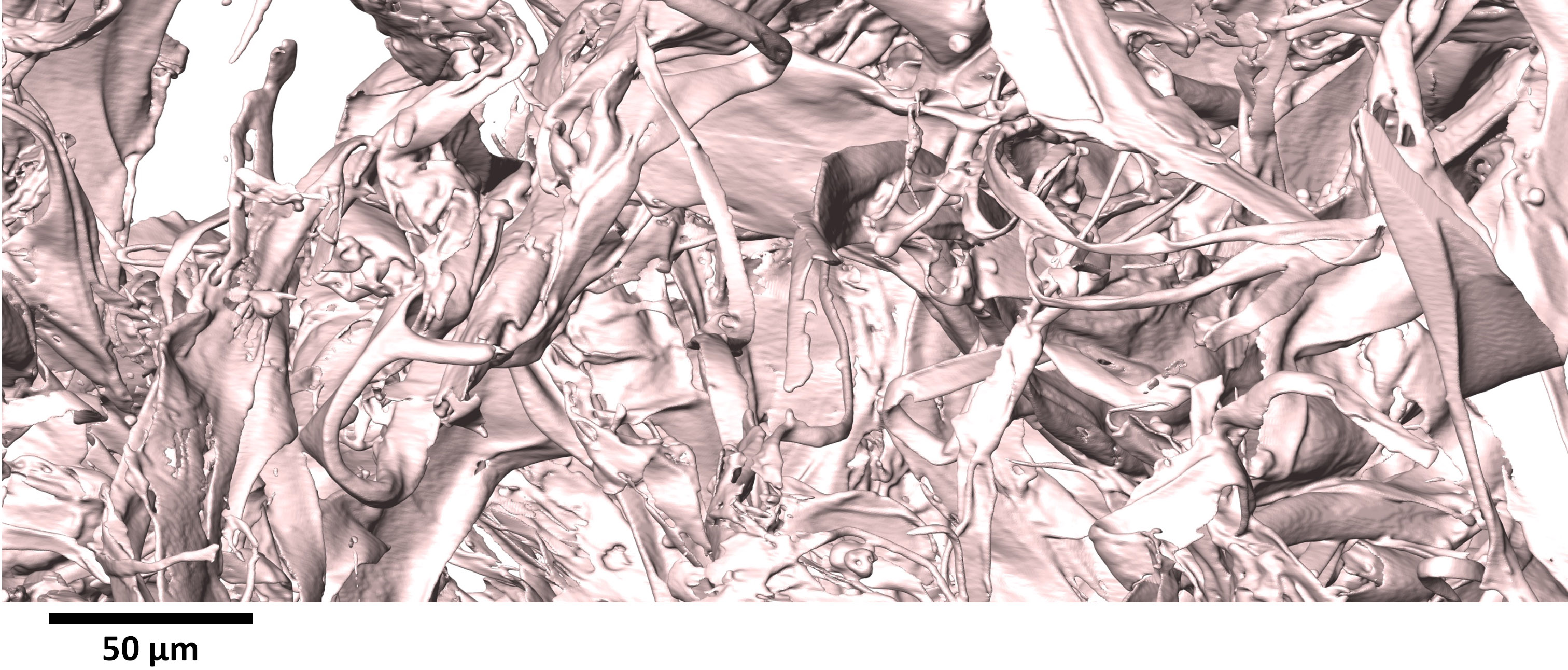

Tissue engineering fabricates bio-compatible composites for improvement or replacement of biological tissues. New designed materials can support the growth of new cells, promote the regeneration and repair of diseased or injured tissues. X-ray computed tomography has become a useful tool for an accurate characterization of these complex 3-dimensional structures, like cryogels (Sedlačík, Soft Matter 2017), hydrogels, hydroxyapatite (Šťastný, J. Am. Ceram. Soc. 2018) or polymeric scaffolds (Vojtová, J. Microsc. 2018). We deals with a methodology of visualizing the scaffolds in sub-micron resolution and make the structure characterization possible (Kalasová, Microsc. Microanal. 2018). The CT results are verified by 2-D imaging techniques (scanning electron microscopy).

Volume rendering of the complex 3-D structure of a collagen-based scaffold measured on our nano-CT Rigaku nano3DX.

Volume rendering of the complex 3-D structure of a collagen-based scaffold measured on our nano-CT Rigaku nano3DX.

Metrology

X-ray computed tomography is now widely used also for measurement of dimensions. Its advantage is the ability to access the internal surfaces, which are not accessible by tactile or optical coordinate measuring machine without destructing the sample.

Spatial resolution

Spatial resolution is one of the significant characteristics of CT systems. It is an ability of CT system to transfer spatial information from the object into the image. It means that the system is able to distinguish spatial details without blurring. The laboratory studies the capability of the spatial resolution determination using measurement of point spread function and the measurement in a scale of spatial frequencies (Lázňovský J., 10thconfiCT 2020). We are developing a software for CT data evaluation according to the ASTM E 1695 and designing the own phantoms for this purpose. The calculation is based on the edge response functions, point spread function and finally the modulation transfer function (Rueckel J., Appl. Radiat. Isot., 2014). Commercially available phantoms like QRM bar pattern or GIMA chart are incorporated to the practical testing.

The MTF function calculated for two different scanning geometries (space filling, circular). The spatial resolution is then in 10 % of MTF.

Uncertainties of CT measurement

The overall process of CT measurement is complex and involves many factors, which prevents precise knowledge of measured values. The uncertainty of measurement expresses this imprecision. There is no measurement model that could evaluate all critical factors affecting a particular CT measurement task.We can estimate the measurement uncertainty by utilizing the substitution method, when repeated CT measurements are compared with reference according to the German guideline VDI/VDE 2630 measurement (poster). Disadvantage of this method is high time and financial cost. Therefore, we focus on the research of effects of various influence factors in order to create a reliable measurement model.

Overview of CT measurement influence factors. According to (Villarraga Gómez et.al., Prec. Eng. 2018).

New reference objects

We are developing new reference objects which can be used for CT system qualification, acceptance and verification testing, correction of error sources or uncertainty determination by substitution methods. Objects used for tactile or optical CMMs are often not suitable due to their high absorbing materials and different characteristics of measurement. CT measurement requires low-absorbing metals like aluminium, ceramic materials and crystals like ruby or carbon composites, as they are X-ray transparent and stable.

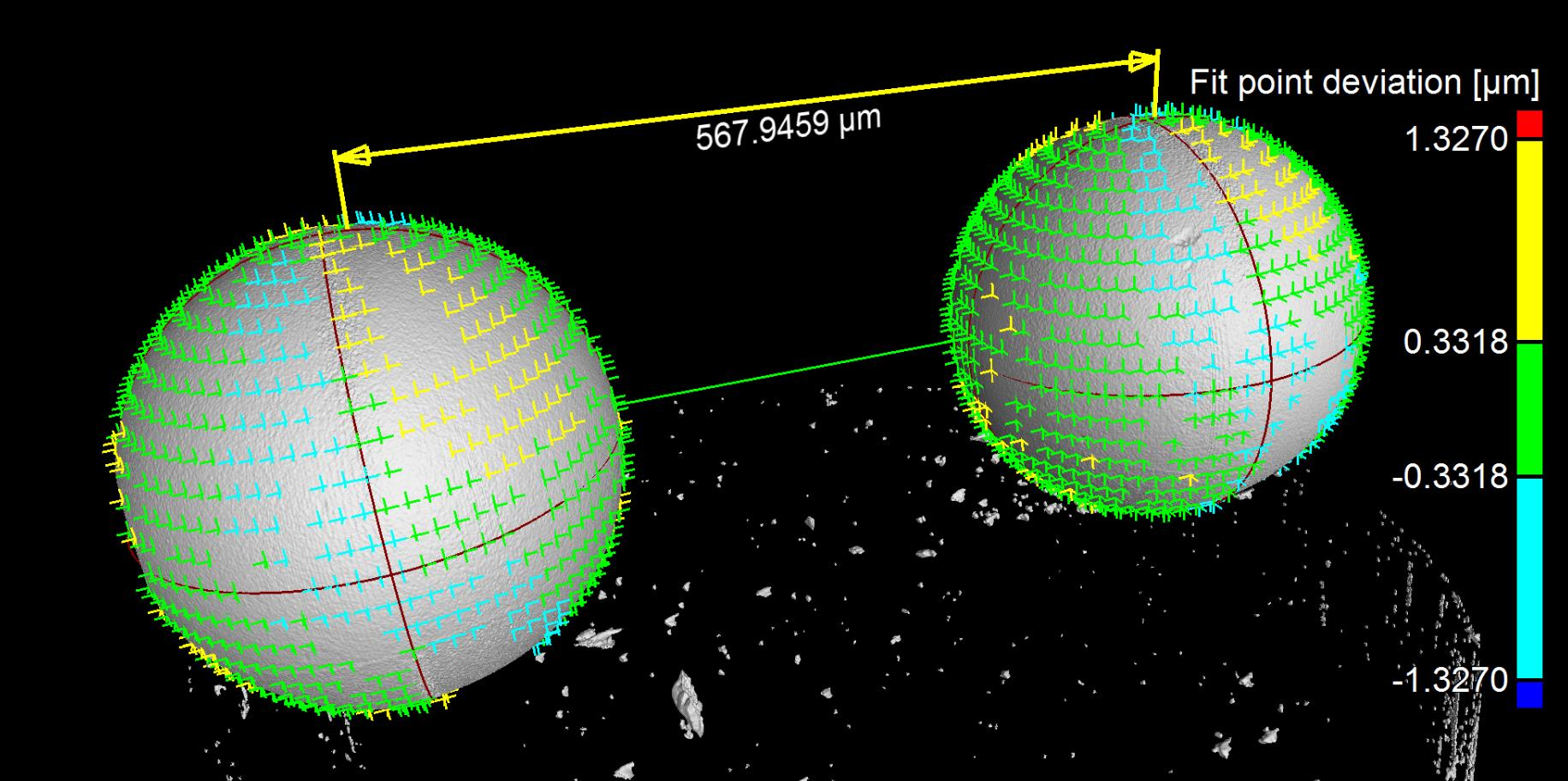

3D visualisation based on CT measurement, phantom for scale calibration of submicron measurement. Distance between two precision ruby spheres of diameter 0.3 mm was calibrated using nanoCMM SIOS NNM-1.

3D visualisation based on CT measurement, phantom for scale calibration of submicron measurement. Distance between two precision ruby spheres of diameter 0.3 mm was calibrated using nanoCMM SIOS NNM-1.

Advanced imaging techniques

X-ray Computed Tomography (CT) technique has been continuously evolving. New techniques are developed and implemented to provide extended informationabout internal structure.

Phase contrast imaging

Phase Contrast Imaging (PCI) is used to extend CT technique for analysing samples with a low X-ray attenuation contrast, such as polymeric structures or soft tissues. For such samples, the X-ray radiation passes the sample structures with no or negligible intensity changes but with altered phase. This phase change cannot be detected directly. Dedicated PCI techniques were developed to visualize either the phase itself or the phase change after passing the sample’s structures. Although PCI technique is used in many variations at synchrotrons, along with the development of X-ray tubes and X-ray detectors, the PCI becomes available also for lab-based CT systems. The research in our laboratory is focused on determining the conditions which each CT device has to fulfil in order to be able to utilize propagation-based PCI methods (Kalasová, IEEE TIM 2019). Apart of investigation of such feasibility, we further aim at studying PCI techniques in general and at developping dedicated methodologies for their practical implementation.

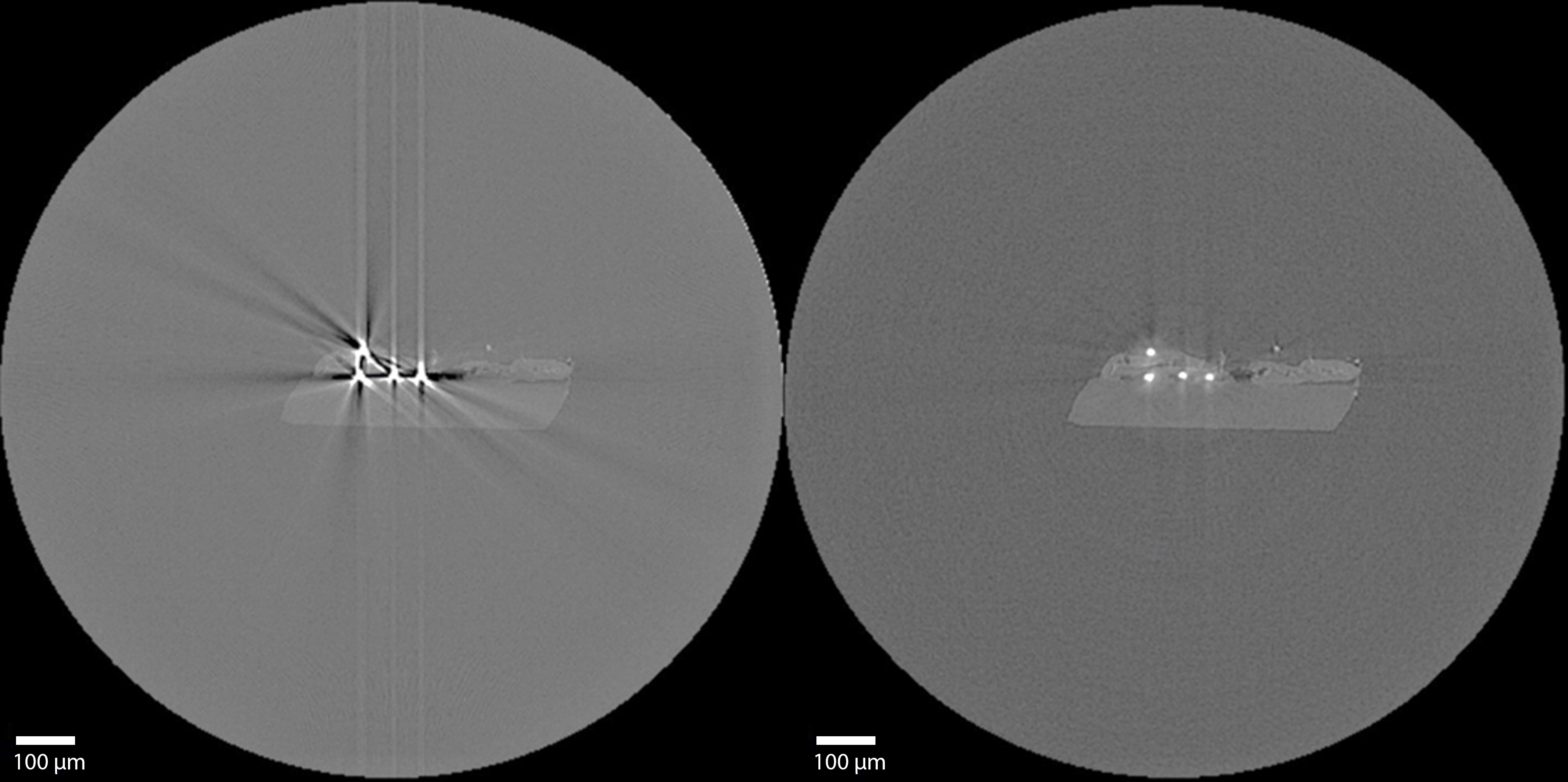

CT slice through PE structure with carbon fibres; left) visualization in absorption contrast; right) visualization in phase contrast.

CT slice through PE structure with carbon fibres; left) visualization in absorption contrast; right) visualization in phase contrast.

Dual-Energy (Dual-Target) CT

Dual-Energy CT (DECT) technique uses two energetically different x-ray spectra for examination and specific differentiation of individual sample components, in terms of materials or tissues, based on their attenuation properties. This differentiation is feasible even for materials which would be inseparable in CT data from the standard single CT measurement. Therefore, the advantage of DECT is the possibility of a precise material segmentation and classification. In our laboratory, we work on the implementation of DECT technique in scope of lab-based nano CT. Our aim is adevelopment of complex methodology for DECT data acquisition and processing to fully utilize possibilities of this promising technique. We work on utilization of DECT for metal artefacts reduction and novel segmentation methods dedicated to biological soft-tissues.

CT slice through structure with Mo fibres; left) original slice; right) slice after DECT metal artifacts reduction.

CT slice through structure with Mo fibres; left) original slice; right) slice after DECT metal artifacts reduction.

Software development

The field of computed tomography relies heavily on the processing power of computer hardware coupled with dedicated processing and reconstruction software. There are many general tomographic software packages, but some samples may need a very specific approach to processing and analysis, which may often not be available commercially. At the CT Lab, we focus on developing custom software for improved quality and easier analysis of tomographic data, from the artifact reduction to efficient automated post-processing.

Tomographic Reconstruction

Tomographic reconstruction is the process of forming cross-sectional images from projections of a sample, and the basis of X-ray computed tomography. Data acquired using a CT scanner is composed of a large number of the object projections at different angles. Information from projection data is then used to reconstruct the internal structure of the sample. Currently, there are two main types of reconstruction algorithms used in computed tomography: analytic algorithms which are efficient and quick, and iterative algorithms which offer great performance in terms of noise suppression and flexibility of scan geometry. Our laboratory focuses on optimizing the reconstruction process for high-resolution tomographic data. We actively collaborate with the hardware manufacturer Rigaku to reduce the limits of tomographic reconstruction, such as enabling CT scanners to scan objects larger than their detector (Zemek, Student EEICT 2020).

Tomographic reconstruction of a slice through a louse at the blue line.

Tomographic reconstruction of a slice through a louse at the blue line.

Artefact Reduction

Artefacts are inconsistencies between the image of an object and the actual object. In computed tomography, the most common artefacts take the form of streaks, rings, geometric differences such as double edges, or incorrect pixel/voxel values, which can severely hinder proper analysis of the dataset. The reduction or removal of artefacts is a complex task, particularly in high-resolution CT data. Tomographic artefacts are of various origin, and need to be approached in different ways based on the manifestation. At our laboratory, we mainly focus on the removal of ring and metal artefacts, as well as the reduction of noise in data.

A CT slice with various types of severe artefacts is on the left, and the same slice after artefact correction is on the right.

A CT slice with various types of severe artefacts is on the left, and the same slice after artefact correction is on the right.

Image processing

Extracting meaningful information from measured CT data is one of the most important tasks in the whole CT analysis procedure. Each CT measurement brings new challenges, some of which the existing software tools are unable to handle. For these kinds of problems, we develop custom programming solutions based on the newest trends in computer vision, including artificial intelligence.

CT image segmentation

A key step in the CT image analysis is segmentation. Image segmentation allows us to isolate only the section of the whole scanned volume that we are interested in and use it for subsequent visualization and analysis. The complexity of the utilized segmentation algorithm depends on the segmentation task at hand. Sometimes, simple thresholding is sufficient, however, in some cases, more advanced solutions are required. These include for example watershed segmentation, deep learning-based segmentation or even manual segmentation.

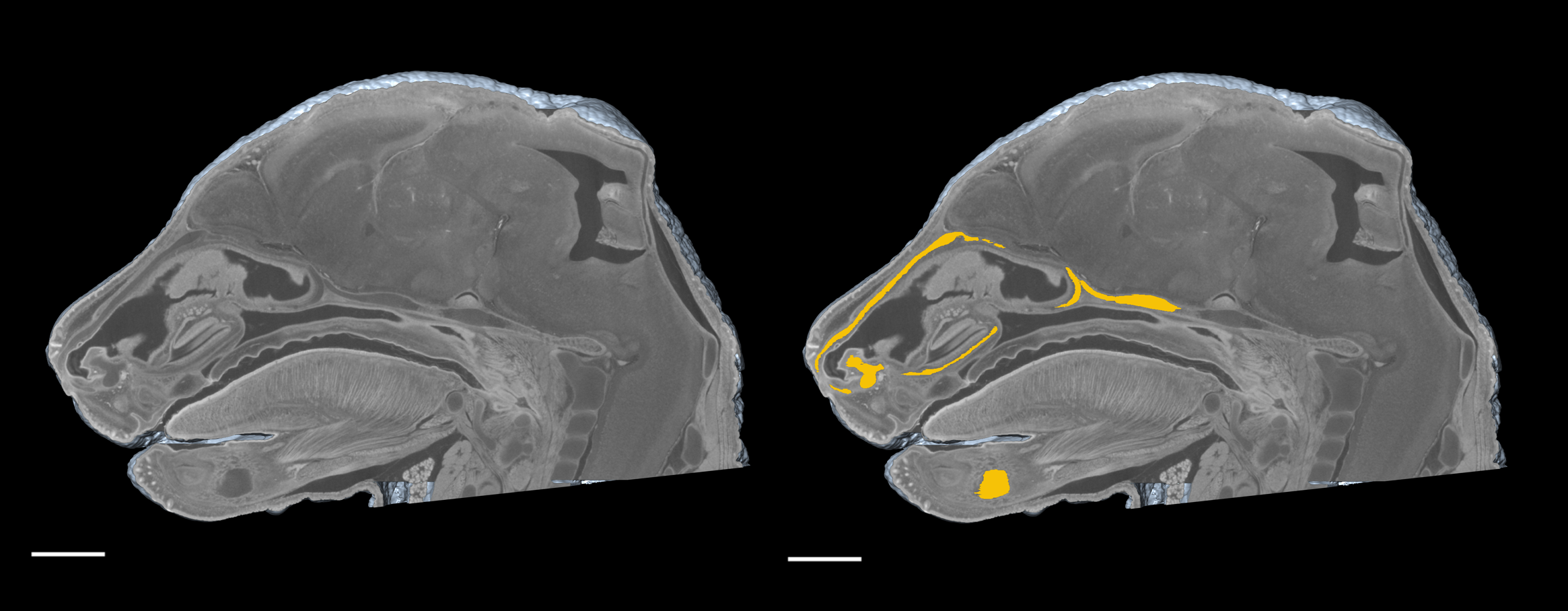

Yellow shows manual segmentation of a mouse embryo nasal capsule in micro-CT image (scale bar 1 mm).

Yellow shows manual segmentation of a mouse embryo nasal capsule in micro-CT image (scale bar 1 mm).

Artificial intelligence and deep learning

Artificial intelligence allows us to utilize the data we have collected over the years of CT measurements and create new exciting fully automatic image segmentation solutions. In deep learning-based segmentation we utilize a set of CT images and a set of manually segmented masks. During an iterative learning process, an image segmentation model is created. It can be subsequently used for segmentation of previously unseen image data.

Comparison of manual and deep-learning based segmentation of Meckel cartilage in the jaw a of a developing mouse embryo.

Comparison of manual and deep-learning based segmentation of Meckel cartilage in the jaw a of a developing mouse embryo.

Applications in various fields

Geology

CT technology enables possibility to analyse geoscientific cores, soils, rocks, minerals (Kalasova, Meteorit Planet Sci 2020), engineered material in a non-destructive way allowing further measurements to have a full spectrum of the sample material and behaviour. The analysis recovers the fields of engineering geology, tectonic but also of hydrogeology, paleontology (Rocek, Sladek, Anat. Rec. 2015), sedimentology, petrology. The features that can be extracted are porosity, density, materials/voids distribution and wall-thickness. All of them can be visualised colour-coded in 2D slices and in a 3D model.

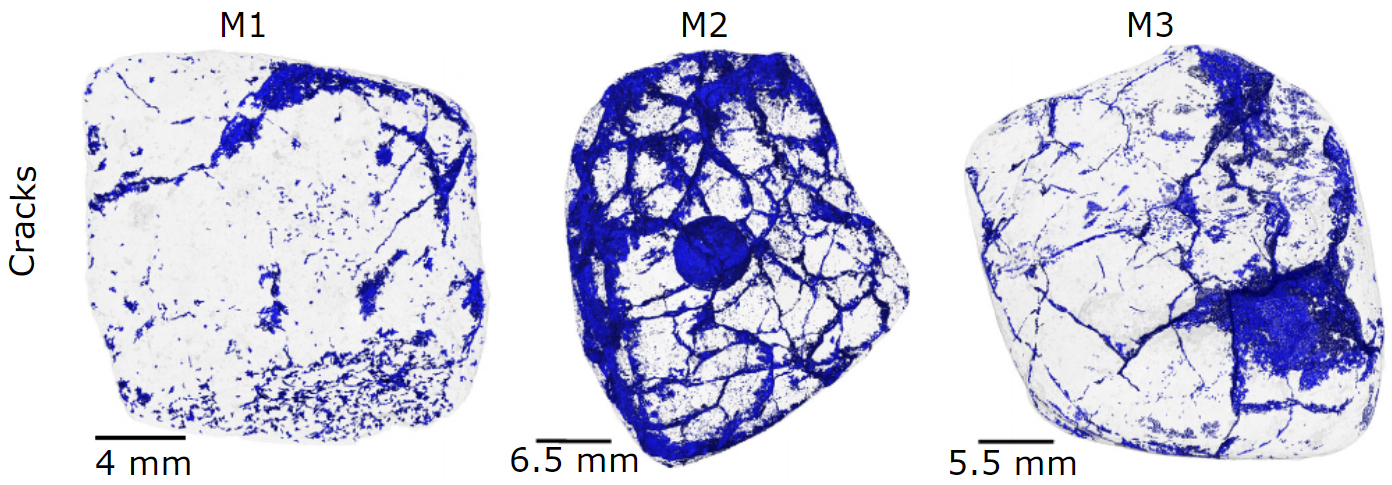

Meteorite cracks shown by blue color.

Restoration (Archeometry)

CT analysis offers a full 2D and 3D inside and out visualisation of sensitive samples, such as paintings, statues (Friml, J. Cult. Herit 2014), archeologic remains from ceramic (Novotna, Spectrochim Acta B 2020), wood to bone and fibers. Historical restoration phases areoften observed.Porosity and damages checks can determine the need for consolidation treatments of endangered artefacts. The exact reproduction of theartefacts for teaching and museum purpose can also be made and used for 3D printing. CT coupled with chemical imaging (MA-XRF, SEM, LIBS) allows a full 3D-dataset reconstruction from artefacts.

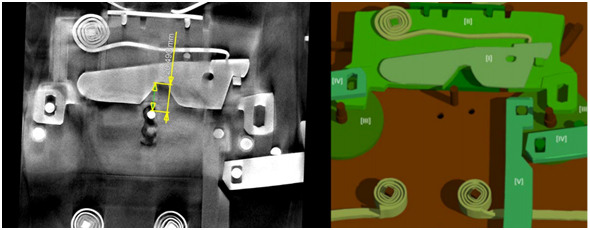

Restoration of lock system of 200 years old chest (Zikmundova, PLOS ONE 2020).

Restoration of lock system of 200 years old chest (Zikmundova, PLOS ONE 2020).